ADVANTAGES

1.The tank body is all made of special alloy steel for pressure vessels or 304 stainless steel, and the accessories are selected from high-quality products to fully guarantee product quality and operating life.

2.Batch type, one time can set a number of different specifications of curtains, high efficiency, highoutput.The effect of setting is achieved through high temperature and high pressure, the drape of the fabric is better, and the wrinkles are not easy to be deformed after washing.

3.The door switch is easy and flexible, the loading and unloading speed is convenient, faster, and the operation is simple.

4.All procedures are automatically completed by the control system. The operation is easy to learn, saving time, worry and cost.

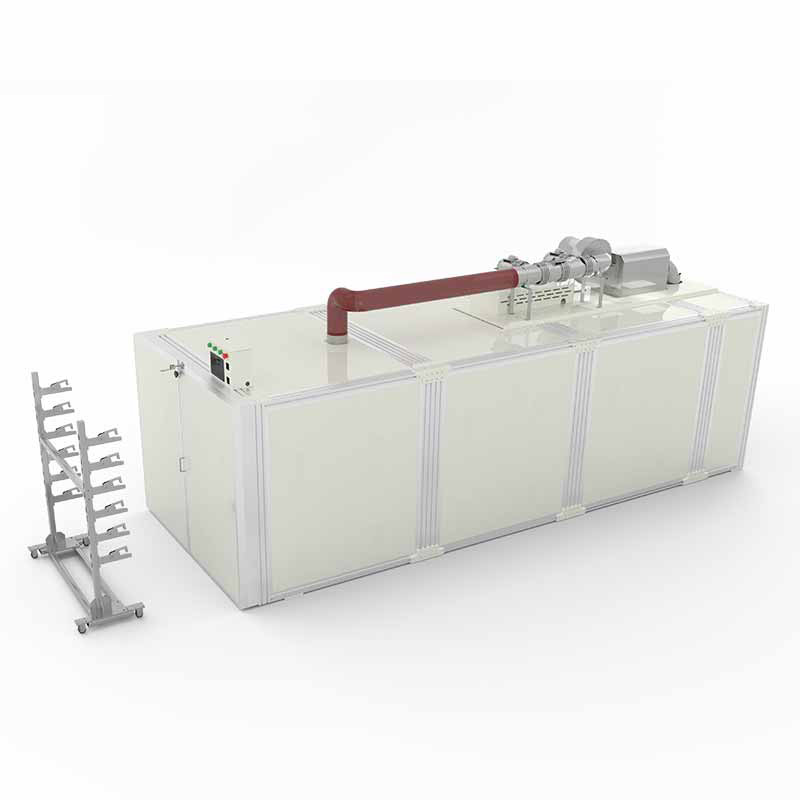

5.The integrated design occupies a small area, and compared with the boiler-type stereotyped airport, the site requirements are much lower, and the use area is reduced.

6.The surface is made of aluminum and filled with 6CM insulation layer, which has better insulation effect and can withstand severe cold and low temperature environment

7.Water can be sprayed repeatedly to soften the fabric and strengthen the setting effect

8.The all-aluminum surface insulation layer has good insulation effect, and it will not rust or stain the fabric after long-term use.

9.Tubular finishing and shaping, simulating the principle of steam softening and ironing for a long time and repeated steaming and baking

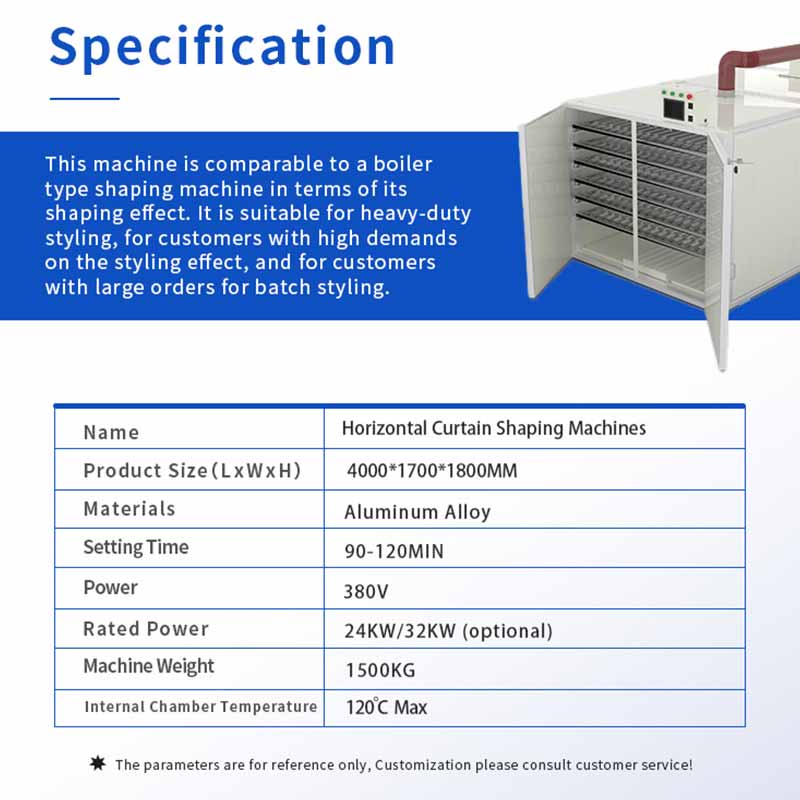

TECHNICAL SPECIFICATIONS

Machine model: RD-WSDXJ400

Rated power: 24KW/32KW

Rated voltage: 380V

Machine size: 4000*1700*1800

Machine weight: 1000KG

Curtain setting time: 90-120 minutes

Video